Professional Machining & Machine Shop Solutions for Custom Industrial Parts

Expert machining and machine shop solutions play a crucial role in the creation of custom industrial pieces. These services serve various industries, ensuring quality and precision in every part. Proficient machinists employ advanced approaches to meet specific project needs. Understanding the details of these processes can considerably influence product deliverables. As industries develop, so too do the technologies that drive these solutions. What does this mean for future manufacturing operations?

Main Benefits of Custom Machined Parts Across Multiple Industries

Though mass-produced components have their place, custom machined parts present distinct advantages that can considerably enhance multiple industries. One of the principal benefits is precision; custom machining allows for exact specifications customized for specific applications, ensuring maximum performance. This level of accuracy reduces the likelihood of errors and lessens the need for adjustments during assembly.

Furthermore, custom machined parts provide greater material versatility, allowing engineers to choose suitable materials according to the environmental conditions and performance requirements. This adaptability can significantly enhance the longevity and durability of components.

Moreover, custom solutions can stimulate innovation, as unique designs can produce improved functionality and efficiency. In sectors such as aerospace, automotive, and medical, where performance is essential, these merits become necessary. In the end, the ability to create specialized parts contributes to increased productivity and competitiveness in different industries.

What Are Precision Machining and Machine Shop Services?

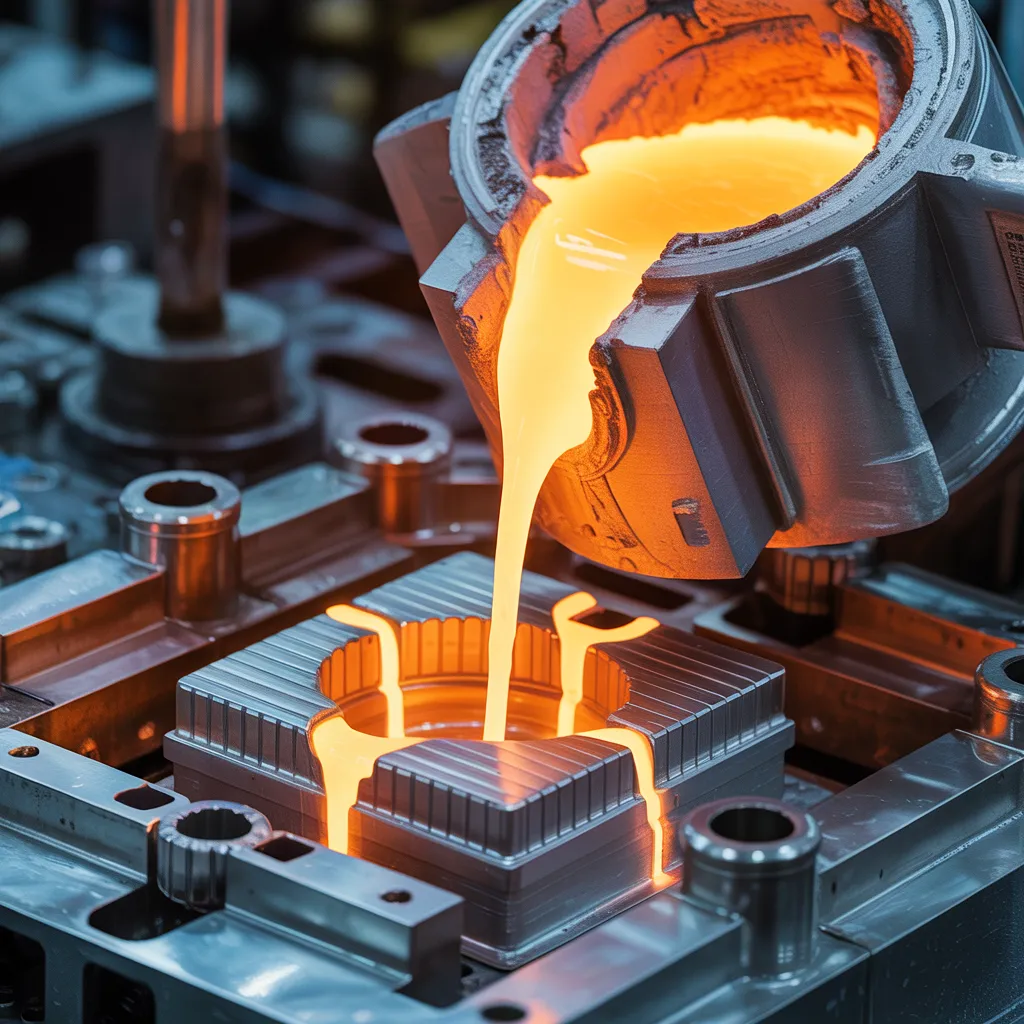

Expert machining and machine shop solutions provide a comprehensive array of services designed to satisfy the demands of multiple industries. These services comprise a range of processes, including accurate machining, CNC machining, milling, turning, and grinding, facilitating the creation of complex and highly detailed components. Expert machinists utilize state-of-the-art technology and equipment to guarantee precision and productivity in fabricating custom parts.

Additionally, expert machining services frequently include design advisory services, prototyping, and quality assurance, making certain that the final products satisfy stringent specifications and industry standards. With capabilities to work with a wide array of materials, from metals to plastics, these machine shop solutions cater to sectors such as aerospace, automotive, medical, and energy. By leveraging knowledge in machining techniques and industry expertise, these service providers help organizations attain their production goals while maintaining excellent outcomes.

Picking the Right Machining Partner: Key Factors to Consider

When choosing the ideal machining partner, what critical factors should be factored in? Initially, the partner's experience and expertise in the applicable industry must be evaluated. This includes assessing their expertise in specific materials and processes pertinent to the project. Moreover, the machining capabilities should correspond to project requirements, such as precision, complexity, and volume.

Another crucial element is the quality assurance protocols in place. A reputable partner will have solid quality control measures to guarantee that all parts meet industry standards. Customer service and communication are similarly vital, as a collaborative relationship can facilitate seamless project execution.

Lastly, cost-effectiveness should be considered, weighing quality against budget restrictions. A detailed evaluation of potential partners using these factors can pave the way for a successful collaboration, in the end delivering high-quality custom parts that fulfill or go beyond expectations.

How Advanced Technologies Are Reshaping Machining Services

Developments in technology are markedly transforming machining services, improving efficiency and precision in the production of custom parts. The integration of computer numerical control (CNC) machines facilitates automated and highly precise operations, reducing human error and enhancing output consistency. Furthermore, the adoption of additive manufacturing technologies enables complex geometries to be created with minimal waste, thereby promoting sustainability.

Software innovations, including CAD and CAM, support better design and simulation processes, allowing engineers to picture and test components before physical production. Furthermore, real-time data analytics and IoT connectivity optimize monitoring and maintenance, contributing to reduced downtime and streamlined production schedules.

These cutting-edge innovations not only improve workflow efficiency but also empower machine shops to respond more swiftly to market demands. As a result, businesses can offer tailored solutions while maintaining competitive pricing and shorter lead times, ultimately changing the landscape of machining services.

Navigating the Process: From Preliminary Model to Full-Scale Production

Though shifting from prototype to comprehensive production can be complicated, a systematic process can optimize this journey. At the outset, clear specifications and design documentation are essential, ensuring that all stakeholders grasp the project requirements. Following this, a detailed evaluation of production capabilities, materials, and technology must be conducted to pinpoint the most suitable methods.

Next, a pilot run is frequently carried out to evaluate the manufacturing process, enabling the identification of potential issues before full-scale production commences. During this phase, collaboration between engineers and production teams helps refining techniques for efficiency and quality assurance.

Once the pilot is validated, scaling up production requires careful planning, including resource allocation and timeline management. Ongoing monitoring and feedback mechanisms will assist in copyright quality and accommodate any unexpected challenges. By following these steps, businesses can effectively shift from prototypes to full-scale production, ensuring both efficiency and product integrity.

Common Questions

Which Materials Are Suitable for Custom Machined Parts?

Various materials can be implemented for custom machined parts, including aluminum, steel, titanium, brass, and plastics. The decision depends on factors such as strength, weight, corrosion resistance, and the specific application requirements.

How Do I Maintain Design Accuracy in My Specifications?

To maintain design accuracy in specifications, one should make use of precise measurement tools, create thorough drawings, engage in comprehensive reviews, and collaborate with experienced engineers. Regular feedback and iterative prototyping can also improve overall precision and reliability.

What's the Typical Turnaround Time for Custom Machining Projects?

Common turnaround time for custom machining projects varies, usually ranging from several days to several weeks. Factors determining this include complexity of get details the project, material availability, and the shop's workload, influencing overall production timelines.

Are There Minimum Order Quantities for Custom Machined Parts?

Usually, custom machined parts come with minimum order quantities, which can change in relation to the complexity level, material, and machining processes involved. These specifications establish optimized production and cost-effectiveness for both the manufacturer and the client.

How Do I Properly Maintain My Custom Machined Parts After Production?

To maintain custom machined parts after production, routine cleaning, lubrication, and inspection for wear are essential. In addition, storing parts in a controlled environment can prevent corrosion and extend their operational lifespan significantly.