Total Aluminum Casting Options for Custom Industrial Components

Comprehensive aluminum casting services offer businesses the capability to produce custom industrial parts customized to their specific requirements. These services utilize advanced techniques such as sand casting, die casting, and investment casting. The produced components are lightweight, robust, and resistant to corrosion, making them suitable for multiple industries. Understanding the advantages and applications of these casting processes can substantially influence production efficiency and quality. What factors should one consider when choosing an aluminum casting service?

The Advantages of Complete Aluminum Casting Services

Although various manufacturing methods exist, total aluminum casting services deliver a unique set of strengths that can considerably boost production efficiency and product quality. This process allows for the creation of intricate designs with high dimensional accuracy, reducing the need for extensive machining. The versatility of aluminum allows the creation of lightweight components without diminishing strength, making it optimal for various applications.

In addition, complete aluminum casting services offer a streamlined production process, decreasing lead times and minimizing material waste. The capability to create large volumes consistently ensures that manufacturers can meet demand without diminishing quality. In addition, aluminum's resistance to corrosion and excellent thermal conductivity add to the longevity and performance of the final products. All in all, these strengths make complete aluminum casting services an attractive option for industries pursuing efficiency, precision, and durability in their manufacturing processes.

Common Applications of Aluminum Cast Parts in Different Industries

Cast aluminum parts are commonly employed across diverse industries due to their remarkable properties and advantages. In the automotive sector, manufacturers rely on these components for engine blocks, transmission housings, and structural frames, leveraging their lightweight nature and corrosion resistance. The aerospace industry also implements aluminum casting for parts such as brackets and housings, which result in reduced weight and improved fuel efficiency.

In the construction sector, aluminum castings are incorporated into window frames, door frames, and roofing materials, increasing aesthetic appeal and durability. Moreover, the electrical industry frequently incorporates aluminum cast parts in enclosures and heat sinks, ensuring superior temperature regulation.

The marine sector appreciates aluminum for its resistance to saltwater practical resource corrosion, utilizing it in components such as engine parts and boat hulls. Overall, the versatility of aluminum cast parts makes them essential across multiple applications, boosting longevity and performance in multiple fields.

Core Aluminum Casting Techniques for Custom Part Creation

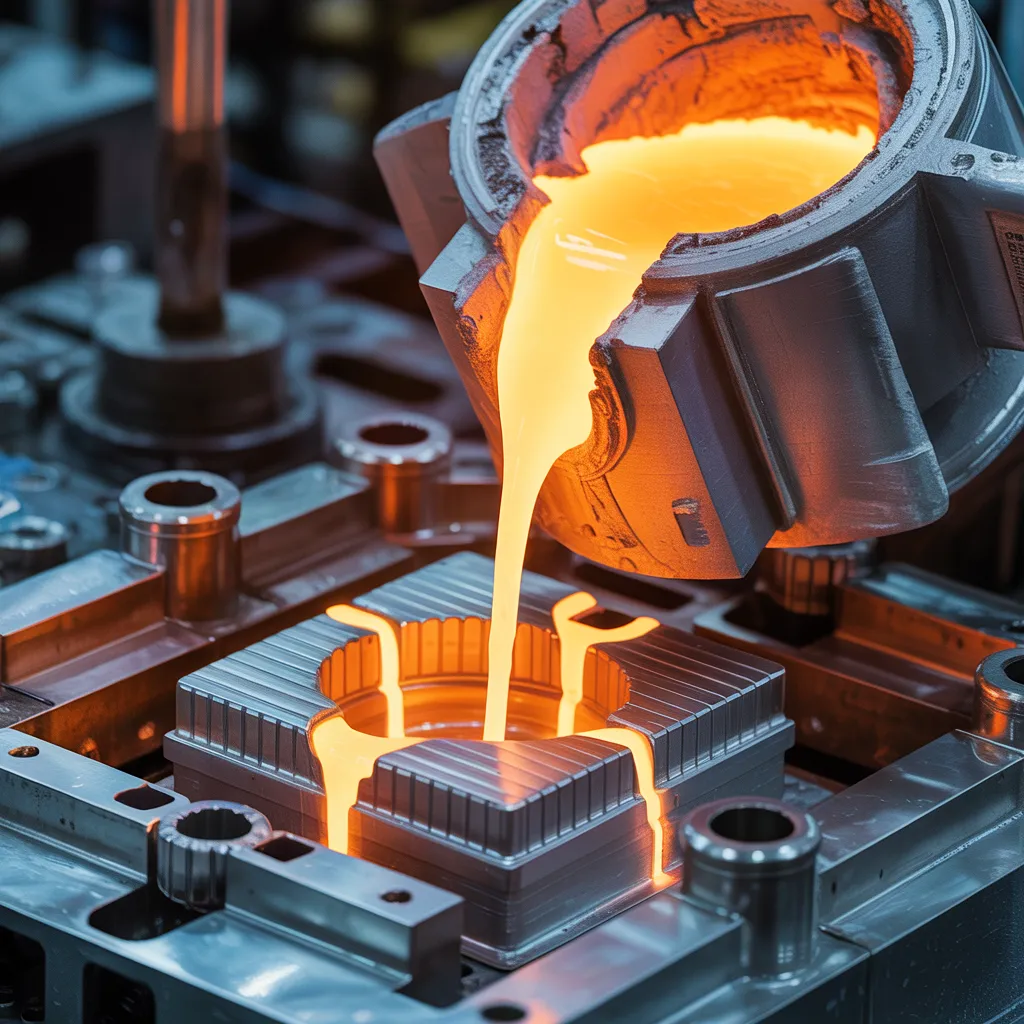

Various essential procedures are employed in aluminum casting to fabricate custom parts that fulfill specific design standards. One widely used method is sand casting, which entails creating a mold from sand and pouring molten aluminum into it. This procedure is excellent for complex shapes and facilitates efficient production of small to medium-sized parts.

Another technique is die casting, where molten aluminum is injected into a metal mold under high pressure. This process is perfect for high-volume production and delivers excellent dimensional accuracy and surface finish.

Investment casting, or lost-wax casting, is another method that enables intricate designs and smooth finishes. This approach consists of developing a wax form that is enveloped in a ceramic shell, which undergoes heating to withdraw the wax and fortify the shell before aluminum is poured.

These methods collectively improve the flexibility and effectiveness of aluminum casting for custom industrial applications.

Picking the Right Aluminum Casting Service?

Choosing the suitable aluminum casting service can significantly affect the success of a project, particularly after understanding the different techniques accessible for custom part production. Future clients should assess several key factors when picking a service provider. First, it is crucial to consider the company's experience and expertise in specific casting methods, such as sand casting or die casting. This confirms the service can meet the particular requirements of the project.

Moreover, customers should review the provider's capacity to handle the intended volume and complexity of parts. Technical capabilities, such as state-of-the-art machinery and software for design, also play a significant role in delivering precision and efficiency.

Another important factor is the company's reputation for customer service and responsiveness, as efficient dialogue can enable more seamless project execution. Eventually, a thorough evaluation of these factors will contribute to a more successful partnership and better project outcomes.

Maintaining Quality Standards in Aluminum Casting

Maintaining excellent quality in aluminum casting is vital for ensuring the longevity and performance of cast parts. To achieve this, several key factors must be considered throughout the casting process. First, selecting top-quality aluminum alloys can substantially affect the final product's strength and resistance to corrosion. Additionally, maintaining exact temperature control during melting and pouring is essential, as variations can result in defects such as porosity or inclusions.

Implementing stringent quality control measures, including NDT procedures and dimensional inspections, guarantees that any issues are spotted early. Moreover, using modern casting techniques, such as investment casting or die casting, can boost dimensional accuracy and surface finish. Finally, continuous training for personnel involved in the casting process fosters a culture of quality awareness, supporting attention to detail. By focusing on these aspects, manufacturers can consistently create high-quality aluminum castings that fulfill the specific needs of their clients.

FAQ

What is the Average Lead Time for Custom Aluminum Casting Orders?

The average lead time for custom aluminum casting orders extends from four to eight weeks, influenced by factors such as design complexity, volume, and production scheduling, which can vary considerably among different manufacturers and projects.

Are You Capable of Handling Small Batch Orders for Aluminum Cast Parts?

Certainly, modest volume orders for aluminum cast parts can be handled. The company understands the varied needs of clients and is capable to handle different quantities without compromising the quality or production schedule.

What Certifications Are Associated with Your Aluminum Casting Services?

The aluminum casting services possess several industry certifications, including the ISO 9001 standard for quality management and ASTM-compliant material specifications. Such certifications ensure adherence to stringent quality and safety protocols during aluminum casting operations.

Can You Offer Design Guidance for Custom Aluminum Parts?

Indeed, they supply design assistance for custom aluminum parts. Their team engages with clients, delivering expertise in material selection, optimization approaches, and CAD modeling to ensure designs fulfill specifications and manufacturing requirements optimally.

What Post-Casting Services Are Available for Aluminum Parts?

Services after casting for aluminum parts typically consist of machining, surface finishing, heat treatment, inspection, and assembly. These additional processes elevate the final product's exactness, durability, and overall quality, ensuring it meets specific industry standards and customer requirements.